X40+ and X50+ Econov

Focus on the essentials

For your fertilization needs, ECONOV

- Free your mind by automating all high-risk operations

- Saves on fertilizer

- Guarantees even distribution throughout the plot

- Removes under- and over-dosed areas

The ECONOV works in widths from 18 to 50 meters up to 4200 l

X40+ and X50+ Econov

Focus on the essentials

- Free your mind by automating all high-risk operations

- Saves on fertilizer

- Guarantees even distribution throughout the plot

- Removes under- and over-dosed areas

X40+ and X50+ Econov

Focus on the essentials

For your fertilization needs, ECONOV

- Free your mind by automating all high-risk operations

- Saves on fertilizer

- Guarantees even distribution throughout the plot

- Removes under- and over-dosed areas

The ECONOV works in widths from 18 to 50 meters up to 4200 l

7-Year Warranty

Sky is now offering a 7-year anti-perforation corrosion warranty for its DX, X, and XT fertiliser distributors, manufactured from 1 September 2019.

7-Year Warranty

Sky is now offering a 7-year anti-perforation corrosion warranty for its DX, X, and XT fertiliser distributors, manufactured from 1 September 2019.

7-Year Warranty

Sky is now offering a 7-year anti-perforation corrosion warranty for its DX, X, and XT fertiliser distributors, manufactured from 1 September 2019.

7-Year Warranty

Sky is now offering a 7-year anti-perforation corrosion warranty for its DX, X, and XT fertiliser distributors, manufactured from 1 September 2019.

The Features

X40+ and X50+ Econov

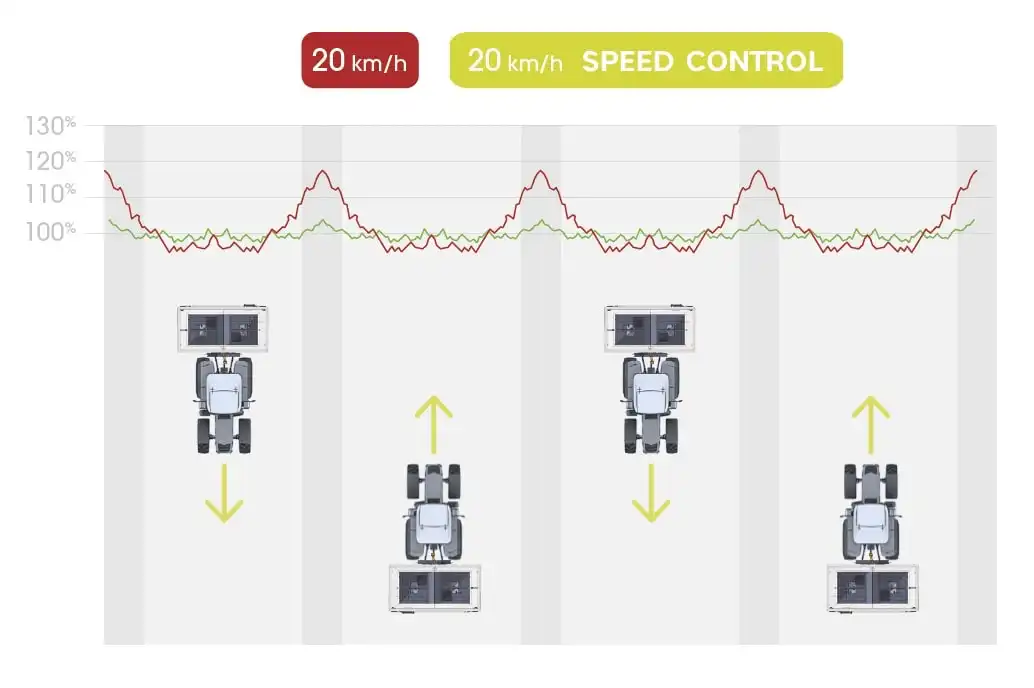

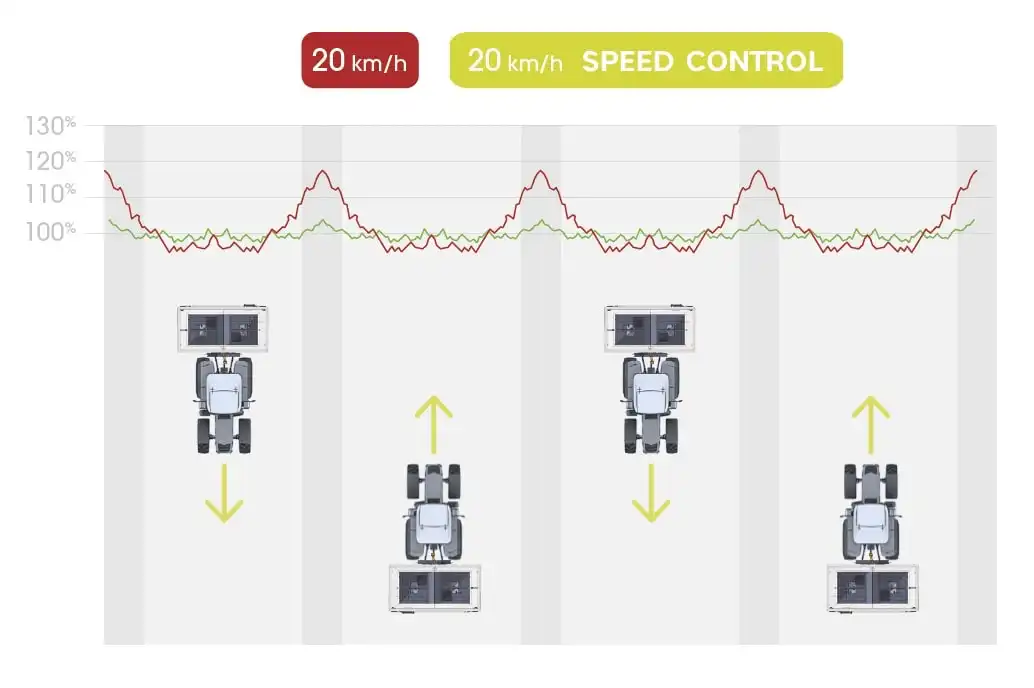

SPEED CONTROL: the new spreading homogeneity technology

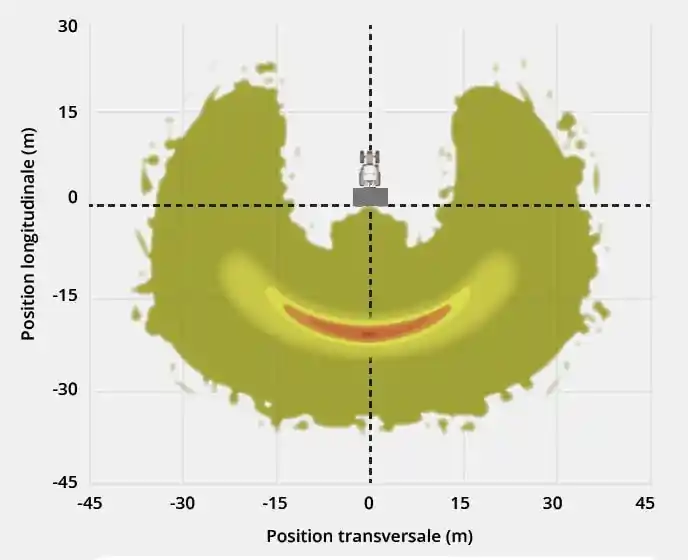

The fruit of 30 years' collaboration with IRSTEA (formerly CEMAGREF), our knowledge of the fertilizer table is unrivalled.

- Control of large widths, taking into account all groundwater parameters

- Fertilizer distribution by height, width and depth

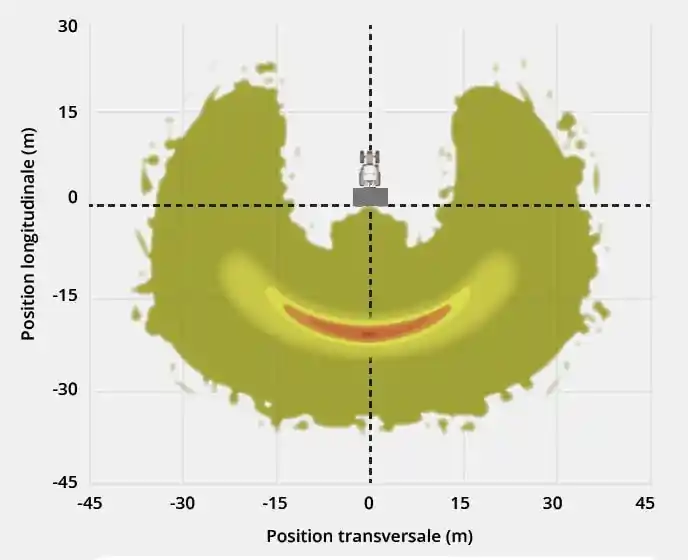

The development of the CEMIB test bench gave us a 3D view of the actual fertilizer slick.

Distribution precision is more than just words...

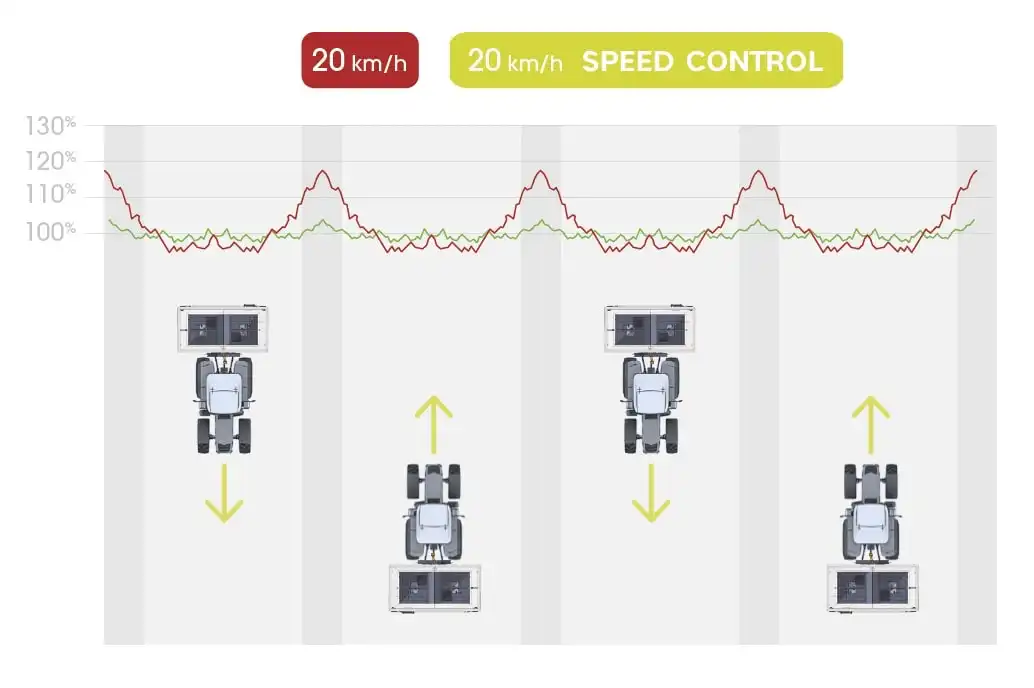

Forward speed is increasingly important when working in the field, and we are developing our mounted and towed implements to absorb these major variations in speed.

SKY's work with INRAE and AgroSup Dijon has shown that the quality of fertilizer distribution in the field varies with forward speed.

Based on this observation, and following a patented concept, SKY has developed a technology for adapting the spreading pattern to the speed of travel: SPEED CONTROL!

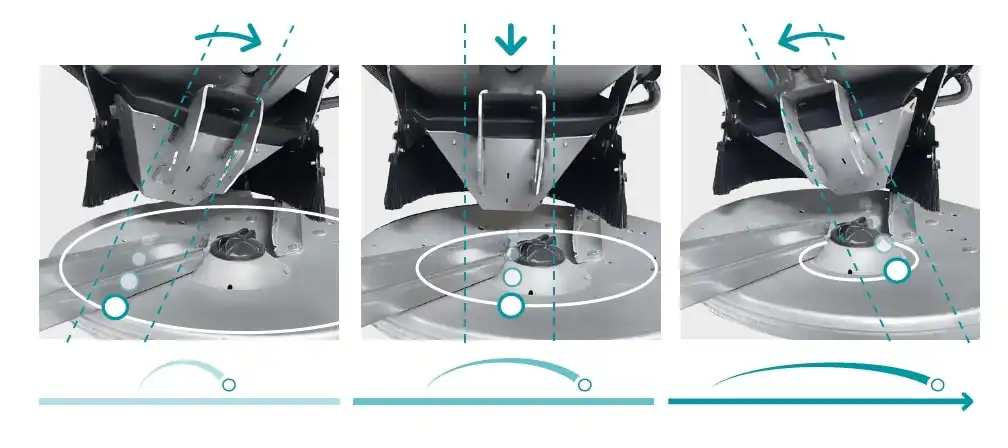

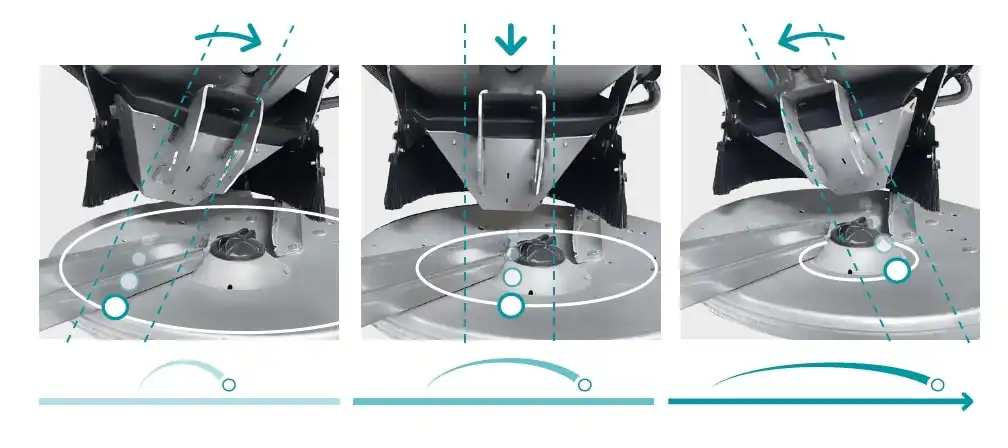

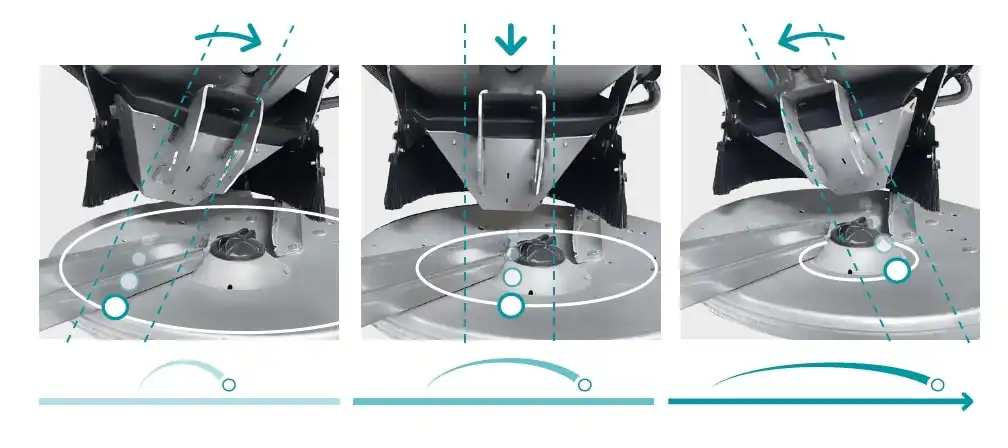

ECONOV, the only technology that manages the actual shape of the spread pattern ... in a curve

- Width adjustment by "infinitely" adjustable chute by changing the feed point on the disc

- Rely on your safety

- No sprockets, plates or even blades to handle, especially when spreading late. Work width adjustment is carried out at a safe distance from moving parts!

Controlling throughput means controlling margins

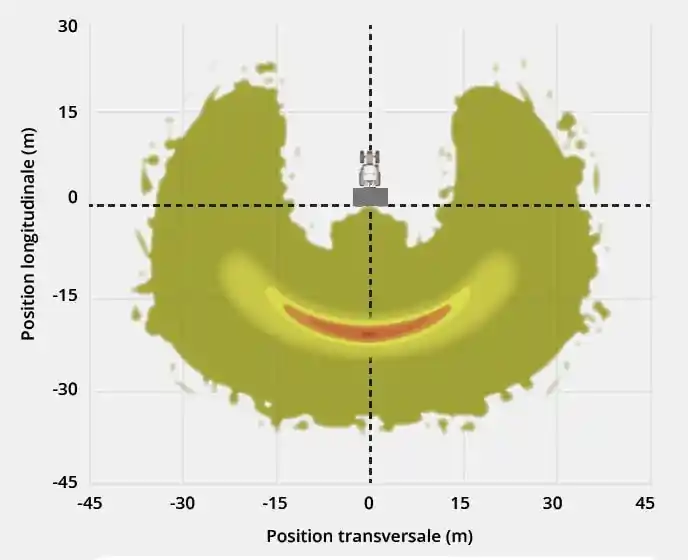

Any fertilizer spread using centrifugal fertilization is curved, not straight.

SKY is the only manufacturer in the world to manage this curved shape from its ISOBUS (QUARTZ 800) and non-ISOBUS (Matrix 840 GS) terminals.

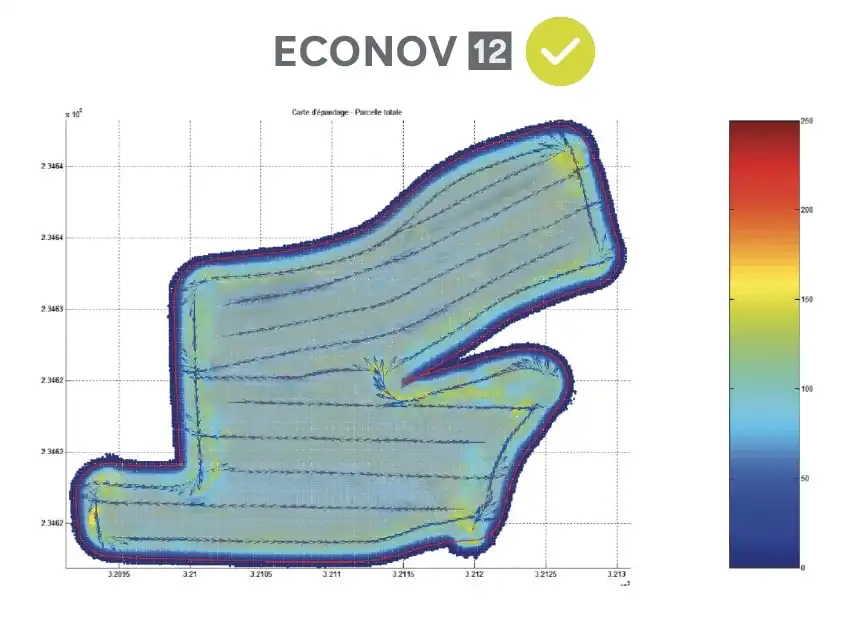

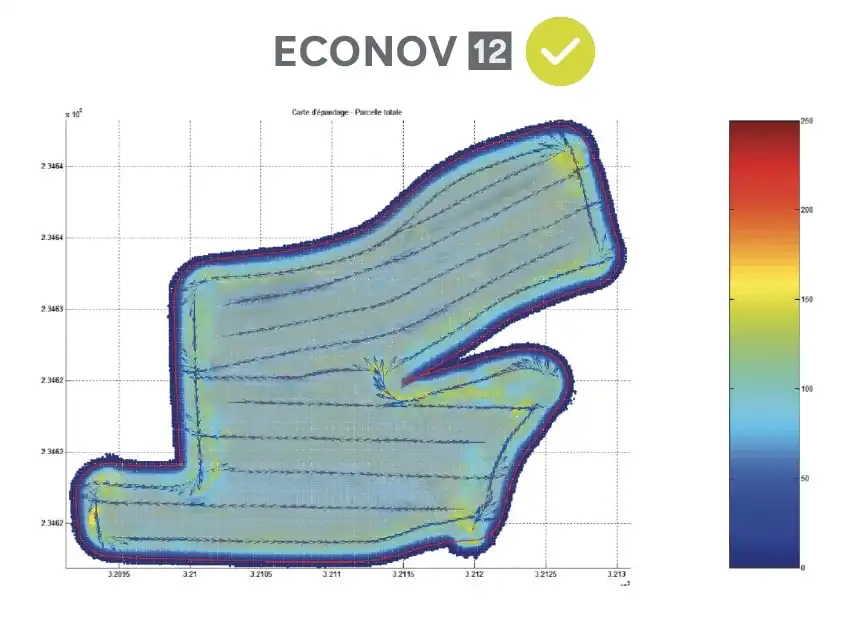

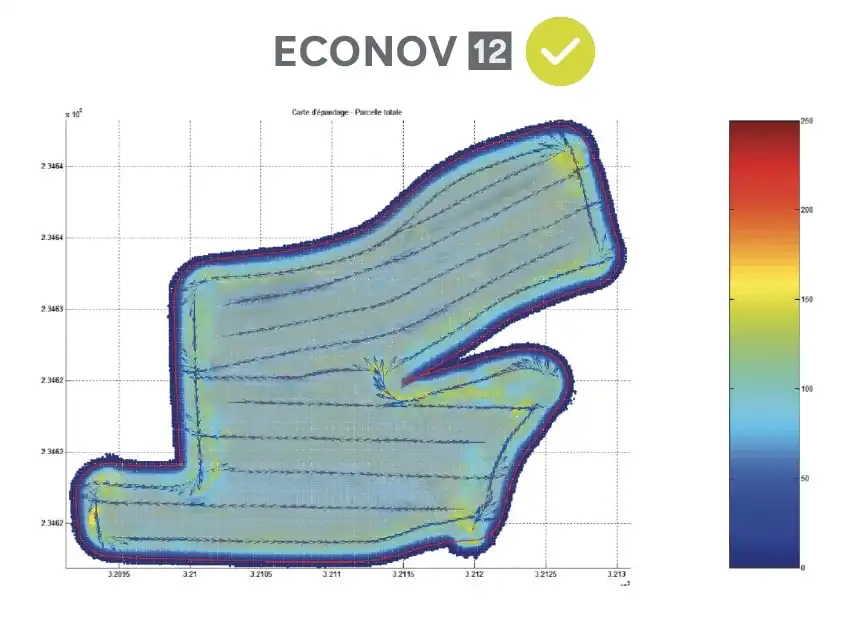

Does Sky technology save on fertilizer?

Yes, according to Emmanuel Piron, whose team carried out the study for Irstea: “Overall, there was a 9% reduction in fertilizer application in favor of Econov, i.e. 1,380 kg applied, compared with 1,515 kg in manual mode with DPAE activated. And above all, areas of under- and over-application are virtually erased in Econov mode.”

1 – Without Econov, many under- and overdoses occur; This spreading map also shows that by choosing a test plot with pronounced shapes, Sky has put itself in real operating conditions.

2 – With Econov, areas of under- and overdosing are virtually eliminated.

With ECONOV, any combination of opening and closing sections is possible.

ECONOV in ISOBUS controls 12 equal sections regardless of working width.

1 - When starting a straight field, the sections gradually open up from the outside inwards, thus respecting the true shape of the spread pattern...in CURVE!

2 - If the spreading width is reduced, for example during the last pass, the sections close automatically according to the remaining spreading width.

Right and left modulation doubles the precision of your modulation

With this feature, you can take your precision farming approach one step further. This makes it easier for you to reach your profitability targets.

From your recommendation card, your Sky fertilizer spreader automatically modulates the fertilizer dose to the right and left.

This technology lets you :

- Reduce areas of over- and under-fertilization,

- Reduce intra-parcel heterogeneity,

- Optimize yields at all points in the plot.

New

SKY offers a new hydraulic spreading disc drive solution, independent of engine speed.

- Simplified hanging

- Homogeneous spreading in all conditions

- Costs under control

SPECIFICATIONS

TYPE

X 40+ Econov

X 40+ Econov

X 40+ Econov

Working width

12-44 m(1)

12-44 m(1)

12-44 m(1)

Flush hopper capacity

1900 / 2050 l

2500 / 2650 l

3000 / 3200 l

Overall width

2,70 m(2)

2,70 m(2)

2,98 m

Useful loading width

2,31 m

2,31 m

2,81 m

Loading height

1,23 m

1,41m

1,52 m

Loading depth

1,17 m

1,17 m

1,17 m

Weight (indicative) weighed version

540 kg

570 kg

585 kg

Payload

3000 kg

3000 kg

3000 kg

1) For optimum working quality, choose the blade set best suited to your application: EV 18-28 m, EV 24-36 m or EV 32-44 m

2) 2.55 m to hopper, 2.70 m to guardrail

TYPE

X 50+ Econov

X 50+ Econov

X 50+ Econov

Working width

24-50 m*

24-50 m*

24-50 m*

Flush hopper capacity

2400 / 2600 l

3200 / 3400 l

4000 / 4200 l

Overall width

2,98 m

2,98 m

2,98 m

Useful loading width

2,81 m

2,81 m

2,81 m

Loading height

1,26 m

1,44 m

1,44 m

Loading depth

1,17 m

1,17 m

1,17 m

Weight (indicative) weighed version

670 kg

705 kg

730 kg

Payload

4000 kg

4000 kg

4000 kg

* For optimum working quality, choose the blade set best suited to your application: EV 24-36 m, EV 32-44 m or EV 40-50 m.

The Features

X40+ and X50+ Econov

Inclined flow hatches: more than just a detail

- Control of large widths, taking into account all groundwater parameters

- Fertilizer distribution by height, width and depth

The development of the CEMIB test bench gave us a 3D view of the actual fertilizer slick.

Distribution precision is more than just words...

Forward speed is increasingly important when working in the field, and we are developing our mounted and towed implements to absorb these major variations in speed.

SKY's work with INRAE and AgroSup Dijon has shown that the quality of fertilizer distribution in the field varies with forward speed.

Based on this observation, and following a patented concept, SKY has developed a technology for adapting the spreading pattern to the speed of travel: SPEED CONTROL!

ECONOV, the only technology that manages the actual shape of the spread pattern ... in a curve

- Width adjustment by "infinitely" adjustable chute by changing the feed point on the disc

- Rely on your safety

- No sprockets, plates or even blades to handle, especially when spreading late. Work width adjustment is carried out at a safe distance from moving parts!

Controlling throughput means controlling margins

Any fertilizer spread using centrifugal fertilization is curved, not straight.

SKY is the only manufacturer in the world to manage this curved shape from its ISOBUS (QUARTZ 800) and non-ISOBUS (Matrix 840 GS) terminals.

Does Sky technology save on fertilizer?

Yes, according to Emmanuel Piron, whose team carried out the study for Irstea: “Overall, there was a 9% reduction in fertilizer application in favor of Econov, i.e. 1,380 kg applied, compared with 1,515 kg in manual mode with DPAE activated. And above all, areas of under- and over-application are virtually erased in Econov mode.”

1 – Without Econov, many under- and overdoses occur; This spreading map also shows that by choosing a test plot with pronounced shapes, Sky has put itself in real operating conditions.

2 – With Econov, areas of under- and overdosing are virtually eliminated.

With ECONOV, any combination of opening and closing sections is possible.

ECONOV in ISOBUS controls 12 equal sections regardless of working width.

1 - When starting a straight field, the sections gradually open up from the outside inwards, thus respecting the true shape of the spread pattern...in CURVE!

2 - If the spreading width is reduced, for example during the last pass, the sections close automatically according to the remaining spreading width.

Right and left modulation doubles the precision of your modulation

Unique on the market, right/left modulation doubles the precision of your fertilizer application modulation.

With this feature, you can take your precision farming approach one step further. This makes it easier for you to reach your profitability targets.

From your recommendation card, your Sky fertilizer spreader automatically modulates the fertilizer dose to the right and left.

This technology lets you :

- Reduce areas of over- and under-fertilization,

- Reduce intra-parcel heterogeneity,

- Optimize yields at all points in the plot.

New

SKY offers a new hydraulic spreading disc drive solution, independent of engine speed.

- Simplified hanging

- Homogeneous spreading in all conditions

- Costs under control

SPECIFICATIONS

TYPE

X 40+ Econov

X 40+ Econov

X 40+ Econov

Working width

12-44 m(1)

12-44 m(1)

12-44 m(1)

Flush hopper capacity

1900 / 2050 l

2500 / 2650 l

3000 / 3200 l

Overall width

2,70 m(2)

2,70 m(2)

2,98 m

Useful loading width

2,31 m

2,31 m

2,81 m

Loading height

1,23 m

1,41m

1,52 m

Loading depth

1,17 m

1,17 m

1,17 m

Weight (indicative) weighed version

540 kg

570 kg

585 kg

Payload

3000 kg

3000 kg

3000 kg

1) For optimum working quality, choose the blade set best suited to your application: EV 18-28 m, EV 24-36 m or EV 32-44 m

2) 2.55 m to hopper, 2.70 m to guardrail

TYPE

X 50+ Econov

X 50+ Econov

X 50+ Econov

Working width

24-50 m*

24-50 m*

24-50 m*

Flush hopper capacity

2400 / 2600 l

3200 / 3400 l

4000 / 4200 l

Overall width

2,98 m

2,98 m

2,98 m

Useful loading width

2,81 m

2,81 m

2,81 m

Loading height

1,26 m

1,44 m

1,44 m

Loading depth

1,17 m

1,17 m

1,17 m

Weight (indicative) weighed version

670 kg

705 kg

730 kg

Payload

4000 kg

4000 kg

4000 kg

* For optimum working quality, choose the blade set best suited to your application: EV 24-36 m, EV 32-44 m or EV 40-50 m.

The Features

DX30+

Inclined flow hatches: more than just a detail

- Control of large widths, taking into account all groundwater parameters

- Fertilizer distribution by height, width and depth

The development of the CEMIB test bench gave us a 3D view of the actual fertilizer slick.

Inclined flow hatches: more than just a detail

Forward speed is increasingly important when working in the field, and we are developing our mounted and towed implements to absorb these major variations in speed.

SKY's work with INRAE and AgroSup Dijon has shown that the quality of fertilizer distribution in the field varies with forward speed.

Based on this observation, and following a patented concept, SKY has developed a technology for adapting the spreading pattern to the speed of travel: SPEED CONTROL!

ECONOV, the only technology that manages the actual shape of the spread pattern ... in a curve

- Width adjustment by "infinitely" adjustable chute by changing the feed point on the disc

- Rely on your safety

- No sprockets, plates or even blades to handle, especially when spreading late. Work width adjustment is carried out at a safe distance from moving parts!

Controlling throughput means controlling margins

Any fertilizer spread using centrifugal fertilization is curved, not straight.

SKY is the only manufacturer in the world to manage this curved shape from its ISOBUS (QUARTZ 800) and non-ISOBUS (Matrix 840 GS) terminals.

Does Sky technology save on fertilizer?

Yes, according to Emmanuel Piron, whose team carried out the study for Irstea: “Overall, there was a 9% reduction in fertilizer application in favor of Econov, i.e. 1,380 kg applied, compared with 1,515 kg in manual mode with DPAE activated. And above all, areas of under- and over-application are virtually erased in Econov mode.”

1 – Without Econov, many under- and overdoses occur; This spreading map also shows that by choosing a test plot with pronounced shapes, Sky has put itself in real operating conditions.

2 – With Econov, areas of under- and overdosing are virtually eliminated.

With ECONOV, any combination of opening and closing sections is possible.

ECONOV in ISOBUS controls 12 equal sections regardless of working width.

1 - When starting a straight field, the sections gradually open up from the outside inwards, thus respecting the true shape of the spread pattern...in CURVE!

2 - If the spreading width is reduced, for example during the last pass, the sections close automatically according to the remaining spreading width.

Right and left modulation doubles the precision of your modulation

Unique on the market, right/left modulation doubles the precision of your fertilizer application modulation.

With this feature, you can take your precision farming approach one step further. This makes it easier for you to reach your profitability targets.

From your recommendation card, your Sky fertilizer spreader automatically modulates the fertilizer dose to the right and left.

This technology lets you :

- Reduce areas of over- and under-fertilization,

- Reduce intra-parcel heterogeneity,

- Optimize yields at all points in the plot.

New

SKY offers a new hydraulic spreading disc drive solution, independent of engine speed.

- Simplified hanging

- Homogeneous spreading in all conditions

- Costs under control